Paper packaging costs vary based on key factors. Material choice affects price—recycled paper is cost-effective, while premium options increase both quality and expense. Design complexity matters too: simple designs are cheaper, but intricate ones hike production costs. Bulk purchasing helps save money—ordering more, especially standard sizes, reduces the unit price. Finally, automation like digital printing eliminates plate-making and cuts labor, while AI optimizes layouts to minimize waste and boost efficiency. These methods balance cost and quality effectively.

Intro

In a world where every dollar counts, packaging costs can quietly eat into your profits. If you’re shipping products across town or from China to North America, those boxes, bags, and shipping fees add up fast. I’ve spent 10 years in the paper packaging game, and trust me—I’ve seen how small tweaks can save big bucks. Whether you’re hunting for affordable options or ways to trim expenses without skimping on quality, you’re in the right place.

This article unpacks your choices with paper packaging—think rigid boxes, corrugated wonders, and more—and hands you practical strategies to lower costs. We’ll cover everything from picking the right materials to tapping into automation, all while keeping sustainability on the table. Ready to boost your bottom line? Let’s get started!

Understanding Packaging Costs

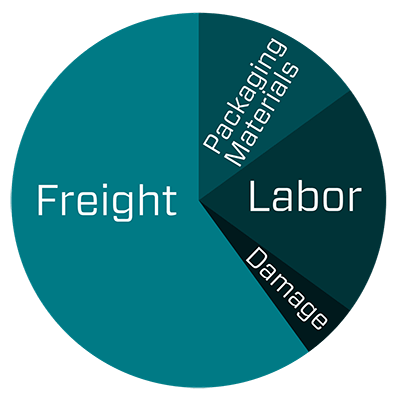

First things first: where’s your money going? Packaging costs break down into a few key buckets:

- Material Costs: This is what you pay for paper, ink, and extras. With paper packaging, prices swing based on whether you’re using recycled or virgin paper1.

- Production Costs: Think printing, cutting, and assembly. A tricky design or slow process can jack up this bill.

- Transportation Costs: Shipping raw materials to your factory and finished goods to customers. Heavy or bulky packaging means higher fees.

- Storage Costs: Warehousing materials and products before they ship. Stack too much, and you’re burning cash on space.

Knowing these pieces helps you spot savings. High material costs? Maybe switch paper grades. Shipping eating you alive? Lighter designs could help. Let’s break it down further.

pie chart of packaging cost breakdown by packaging manufacturer

Why Paper Packaging Rocks

Paper packaging isn’t just tree-hugging hype—it’s a cost-saver too. Here’s why it’s a smart pick for businesses aiming to balance quality, sustainability, and their budgets:

Sustainability: happy planet, happy sales

Paper packaging shines when it comes to sustainability, offering benefits that go beyond feel-good environmentalism. Because it’s recyclable and biodegradable, paper significantly reduces the amount of waste heading to landfills. This isn’t just good for the planet—it’s a direct cost-saver for businesses.

Disposal fees for non-recyclable materials like plastic or metal can stack up quickly, but with paper, you’re looking at lower end-of-life costs since it can be recycled or left to break down naturally. In some regions, businesses can even turn a profit by participating in recycling programs that pay for collected materials.

But the advantages don’t stop at cost-cutting. Sustainability is a powerful sales driver in today’s market. According to a NielsenIQ study, 66% of consumers are willing to pay a premium for eco-friendly products. That’s a massive chunk of the market prioritizing green choices, and it’s growing every year.

By choosing paper packaging, you’re not just reducing operational expenses—you’re positioning your brand as a leader in sustainability. This alignment with consumer values can lead to increased customer loyalty, higher sales, and a reputation that sets you apart from competitors. It’s a double win: a happier planet and a healthier bottom line.

Wallet-Friendly: cheaper end-of-life costs

When it comes to keeping costs in check, paper packaging is a financially savvy choice that holds its own against pricier alternatives like plastic or metal. At first glance, the upfront cost of paper might seem comparable to other materials, but the real savings kick in when you consider the full lifecycle.

Paper often starts with competitive material costs, especially if you opt for recycled or sustainably sourced varieties, which are widely available and increasingly affordable. Modern manufacturing processes have also made production more efficient, cutting down on labor and time-related expenses that can inflate costs with more complex materials.

Where paper really pulls ahead, though, is at the end of the line. Its recyclable and biodegradable nature means lower disposal fees—a stark contrast to plastic, which can incur hefty waste management costs, or metal, which requires energy-intensive recycling processes. For businesses shipping in bulk or operating on tight margins, these savings add up fast.

For procurement managers, this translates to a lower total cost of ownership, where the focus isn’t just on the initial price tag but on long-term value. Paper packaging proves that you don’t have to sacrifice quality to keep your budget intact.

Custom Vibes: easy printing and finishing

Paper packaging offers a creative and cost-effective solution to elevate your brand. Its flexibility makes it easy to customize with vibrant prints, intricate designs, or finishes like embossing and foiling, allowing you to create standout packaging—sleek and minimalist or bold and eye-catching. Compared to metal or plastic, which are costlier and harder to customize, paper keeps things simple and affordable.

At C MIC Packaging, our rigid boxes provide a premium, luxurious feel at a fraction of the cost, enabling businesses of all sizes to iterate quickly, test new designs, and launch seasonal packaging while staying competitive and budget-friendly.

Light as a Feather: weighs less, shipping costs reduce

Paper packaging’s lightweight design offers businesses a clever way to slash shipping costs. Unlike heavier plastic or metal alternatives, paper reduces package weight, cutting fuel consumption and avoiding oversized package surcharges—savings that stack up significantly for bulk or international shipments from Shenzhen to Chicago. Its stackability also optimizes warehouse space, boosting efficiency.

Blending affordability, sustainability, and customization, paper stands out as a cost-effective, global solution. Now, let’s explore ways to make it even cheaper—who doesn’t love squeezing out a little extra value?

sustainable corrugated boxes

Your Cost-Cutting Toolkit

Here’s how to shrink those packaging bills with paper-based tricks:

Material Selection

The paper you choose can make or break your budget. For everyday items, low-grade or recycled paper is a no-brainer. Think corrugated boxes2—they’re tough enough and way cheaper. Take one of our jewelry distributor in Western Europe: they swapped to recycled stock for their subscription shipping boxes and cut material costs by 23.7%. Quality didn’t take a hit either.

For upscale products, premium paper like our rigid boxes keeps that high-end vibe without blowing the bank. Sourcing plays a big role too. Local suppliers cut shipping fees, perfect for tight budgets. But if you need top-notch quality, global sourcing can score killer deals. At C MIC Packaging, we leverage Shenzhen’s shipping lanes to North America, blending affordability with excellence. Pick smart, and your savings stack up fast.

recycled pulp packaging vs. premium paper boxes

Design Optimization

Smart design is a game-changer. Here’s the playbook:

- Fit It Tight: Boxes should hug your product like a glove. Less material means less waste and smaller shipping boxes. Greener Corporation redesigned their boxes to fit snugly, dropping material costs by 20% and trimming shipping fees too. See how to correctly measure and determin the right packaging size.

- Keep It Simple: Ditch crazy shapes and fancy folds. Straight cuts and basic designs speed up production and cut labor costs. Fewer steps, fewer headaches.

- Go Standard: Stick to standard sizes whenever you can. They unlock bulk discounts and zip through assembly lines. Plus, they stack neatly, saving warehouse space.

- Custom In Bulk: Need a special size? Go big with bulk orders. It’s like hitting two birds with one stone—you get exactly what you need and save cash, just like we talked about in point 3.

One tweak can spark big wins. At C MIC Packaging, our custom design services help you strike the perfect balance between style and savings—plus, we offer a free consultation to kick things off. Designers enjoy creative freedom, while managers gain efficiency. It’s a win-win that starts with a simple, no-pressure chat.

efficient packaging insert design for bunch of cosmetics

Bulk Purchasing

Buying in bulk can slash costs—if you don’t overdo it. It’s gold for steady packaging needs, like retail or e-commerce. Logiwa, a logistics firm, used the Economic Order Quantity (EOQ) formula to perfect their orders. They saved 10% on storage by ordering just enough—no excess cluttering their warehouse.

Economic Order Quantity (EOQ) is a formula that helps businesses determine the ideal order size to minimize the total costs of ordering and holding inventory. It balances ordering costs (e.g., shipping fees) and holding costs (e.g., storage expenses). The formula is:

EOQ = √(2DS/H)

where:

- ( D ) is the annual demand,

- ( S ) is the cost per order,

- ( H ) is the holding cost per unit per year.

EOQ sounds fancy, but it’s simple: it calculates the ideal order size to minimize costs. You save on bulk discounts without drowning in inventory. Watch out, though—overstocking eats into profits with storage fees. For seasonal businesses, mix bulk buys with smaller, on-demand orders. Stay sharp, and the numbers work in your favor.

Leveraging Technology

Tech isn’t just cool—it’s a cost-cutting powerhouse. Automated cutting and folding machines trim labor costs and turbocharge production. A packaging plant added automation and slashed labor expenses by 25%, per a Packaging Digest report. Speed went up; errors went down.

Digital printing3 rocks for short runs. No plate setup means lower costs and quick turnarounds—ideal for limited batches or test designs. Then there’s AI, suggesting layouts that use every inch of paper, cutting waste. IoT tracks stock live, so you’re never overstocked or scrambling. These aren’t gadgets—they’re profit boosters.

Mix and match these based on your gig—buyers love bulk deals, designers dig optimization, and managers thrive on tech.

Real-World Wins

Need proof? Check these success stories:

Retail Company Saves 15% with Recycled Paper

A study in the Journal of Sustainable Development examined a medium-sized retail company that switched from virgin to recycled paper for its shipping boxes. The research found that this move saved them 15% on material costs, with no compromise on box durability or customer satisfaction. The company’s CEO noted, “It was a win-win: we saved money and did good for the planet.” This example shows that choosing sustainable materials can also be cost-effective, appealing to procurement decision-makers focused on ROI and sustainability.

Cosmetics Firm Cuts Costs by 10% Through Redesign

In the International Journal of Design, researchers detailed how a cosmetics firm redesigned its packaging to use less paper. By optimizing the box size and shape, the company reduced material usage by 20%, leading to a 10% decrease in production costs. The design team leader remarked, “It’s amazing how a little tweak can make such a big difference.” This case highlights the financial benefits of design innovation, resonating with designers and packaging managers seeking efficiency and aesthetic appeal.

Food Manufacturer Reduces Storage Costs by 30% with JIT

The Journal of Supply Chain Management shared a case where a food packaging manufacturer implemented a Just-in-Time (JIT) inventory system. The implementation resulted in a 30% reduction in storage costs and a significant decrease in waste from excess stock. The plant manager commented, “JIT has been a game-changer for us. It’s freed up capital and made our operations leaner.” This example underscores the economic benefits of lean inventory management, appealing to C-suite executives focused on strategic cost control.

| Case Study | Strategy | Cost Saving |

| Retail Company | Material Selection | 15% on materials |

| Cosmetics Firm | Design Optimization | 10% on production |

| Food Packaging Manufacturer | Inventory Management (JIT) | 30% on storage |

These wins show what’s possible with a little strategy.

Dodge These Costly Slip-Ups

Cutting corners can backfire. Watch out for these traps:

- Quality Cuts: Cheap paper might save now, but damaged goods cost more later.

- Hidden Costs: Don’t just eye materials—production and shipping can bite too.

- Sustainability Skip: Eco-friendly might cost more upfront, but it saves on disposal and wins customers.

- Scale Snafus: What works small might flop big—plan ahead.

Steer clear, and your savings stick.

Best Practices to Nail It

Make these habits your go-to:

Audit Regularly: Find the Leaks

Costs can sneak up on you like a slow leak in a tire—barely noticeable until you’re flat broke. That’s why digging into your expenses yearly (or even twice a year if you’re feeling ambitious) is a must. It’s your chance to spot the leaks: overpriced materials, wasteful processes, or that one machine that’s guzzling energy like it’s free.

Grab tools like cost-benefit analysis or lean manufacturing principles to X-ray your budget. For instance, a snack company audited their line and found they were using 20% more plastic film than necessary—tweaking it saved them a cool five figures in a year. Don’t let cash slip through the cracks; regular audits keep your profits plugged in.

Team Up with Suppliers: Unlock Deals and Ideas

Your suppliers aren’t just order-takers—they’re your secret weapon. Chatting them up and building real relationships can score you better deals, fresh ideas, and even custom solutions you’d never dream up solo. Think bulk discounts, exclusive pricing, or co-designing a lighter package that cuts shipping costs.

At C MIC Packaging, we’ve seen clients reduce their bills by an average of 7% just by getting cozy with us. Want in on that? Contact C MIC Packaging for a free consultation—we’ll dig into your supply chain and show you how to save big, together. Strong supplier vibes don’t just pay off—they pay dividends.

Train the Crew: Sharpen Skills for Savings

Your team’s brainpower is your goldmine. Keep them in the know with ongoing training on cost-saving tricks—think workshops on efficient packing techniques or a crash course in waste reduction. Cross-train them so they’re flexible, or gamify it with a “who can save the most” challenge. One company we worked with cut waste by 5% after a single afternoon session—turns out, a little know-how goes a long way. Knowledge isn’t just power; it’s profit waiting to happen.

Trend-Spot: Stay Ahead with Tech and Materials

The packaging game doesn’t sit still, and neither should you. New tech and materials can flip the script on costs overnight—think digital printing for cheaper small batches or biodegradable films that trim waste fees. AI’s even jumping in, optimizing designs to use less ink or cardboard. Stay sharp by skimming industry blogs, hitting up trade shows, or just keeping an ear to the ground. Spotting trends early is like getting a cheat code for your budget—use it to stay one step ahead.

Green It Up: Save Cash and Build Your Rep

Sustainable moves aren’t just for tree-huggers—they’re money-savers with swagger. Switching to recycled materials or tweaking your line for less energy use can slash costs fast. Bonus: customers eat it up. You’re not just saving—you’re building a rep that pulls in sales. It’s a win-win that hits the bottom line and the feels, all in one sharp shot.

Wrap-Up: Save Smart, Win Big

Cutting packaging costs isn’t about cheap hacks—it’s about sharp moves that last. Pick the right paper, streamline designs, buy smart, and lean on tech. You’ll save big without losing what matters: quality and that eco-edge customers love.

I’ve watched companies transform their bottom line with these steps—some I’ve helped myself at C MIC Packaging. Whether you’re boxing jewelry or shipping gadgets, we’ve got your back. Swing by C MIC Packaging to see how our custom solutions can trim your costs and amp your game. Take a peek, tweak your approach, and watch profits climb—it’s that simple.

🎁