To measure the right packaging size, determine your product’s dimensions (length, width, height), add clearance for protection (0.5–1 inch), and account for inserts or branding elements. Use these measurements to select a box that balances cost, safety, and presentation.

Intro: Why Packaging Size Matters More Than You Think

Picture this: You’ve spent months perfecting your product, from its design to its marketing campaign. It’s finally time to ship it to your customers. But when the package arrives, the box is crumpled, the product is damaged, or worse—there’s so much empty space it looks like you’re shipping air. Sound familiar? Choosing the right packaging size isn’t just about fitting a product into a box. It’s about protecting your goods, cutting costs, enhancing your brand, and even saving the planet.

I’ve seen this firsthand in my 10 years at packaging industry, where I’ve worked with businesses of all sizes to solve their packaging woes. Whether you’re a designer sketching out a luxury rigid box or a department person in charge crunching numbers on shipping costs, getting the packaging size right is a game-changer. In this guide, I’ll share practical steps, real-world examples, and insider tips to help you measure and determine the perfect packaging size for your needs. Let’s dive in! — Adam Y.

Measure the Right Product & Packaging Size

Before you even think about picking up a tape measure, you need to understand what your product demands from its packaging. This isn’t just about size—it’s about protection, presentation, and practicality. Let’s break it down into the key factors every packaging buyer, manager, or executive should consider.

Analyze Your Product’s Dimensions

The first step is to measure your product accurately. Sounds simple, right? But I’ve seen countless businesses skip this step or get it wrong, leading to oversized boxes or, worse, damaged goods. Grab a ruler or tape measure and note down the length, width, and height of your product at its widest points. If your product has irregular shapes—like a bottle with a narrow neck but a wide base—measure the largest dimensions to ensure it fits comfortably.

Let’s break it down into simple steps anyone can follow, even if you’ve never measured anything before. The goal is to find the largest dimensions—the biggest length, width, and height—so your product fits perfectly in its packaging without wasting space or risking damage.

- Gather Your Tools: You don’t need anything fancy—just a ruler or tape measure and a piece of paper to write down your numbers. A tape measure is better for larger or oddly shaped items because it’s flexible, but a ruler works fine for smaller, flat products.

- Place Your Product on a Flat Surface: Put your product on a table or desk so it’s stable and easy to measure. If it’s something wobbly, like a bottle, you might need to hold it steady or lay it down flat. The key is to position it so you can see and reach all sides.

- Measure the Length (Longest Side): Look at your product and find its longest side—this is the length. Use your ruler or tape measure to measure from one end to the other. For example, if you’re measuring a book, the length is the distance from the up edge to the down edge of the cover. Write down this number.

- Measure the Width (Side to Side): Next, find the width, which is the distance from the front to the back of your product. Turn your product if needed to see this side clearly. For the book example, the width would be the distance from the the left edge to the right edge. Write this number down too.

- Measure the Height (Top to Bottom): Finally, measure the height, which is the distance the front cover to the back cover. For the book, this would be the thickness from the bottom page to the top page when it’s lying flat. If your product is standing upright, like a bottle, measure from the base to the top. Write down this number as well.

- Double-Check Your Numbers: Before you move on, measure each side again to make sure your numbers are accurate. It’s easy to misread a tape measure or write down the wrong number, especially if you’re in a hurry. If your product has parts that move or stick out, like a mug with a handle, make sure you’ve included those in your measurements. For instance, a mug might be 3 inches wide without the handle, but 4 inches wide including it—use the larger number.

How to handle irregular shapes? -Find the Largest Dimensions1.

If your product isn’t a perfect rectangle, like a bottle with a narrow neck but a wide base, you need to measure the largest dimensions. This means finding the widest, longest, and tallest points, even if they’re not in a straight line.

For example, a bottle might have a base that’s 3 inches wide but a cap that sticks out an extra half-inch. In this case, you’d measure the total width as 3.5 inches to include the cap. Similarly, if the bottle is 8 inches tall but has a decorative topper that adds another inch, the height would be 9 inches. Always measure the outermost edges to capture the biggest size in each direction.

By following these steps, you’ll have a clear set of dimensions—length, width, and height—that represent the largest size of your product. These numbers are the foundation for choosing the right packaging, ensuring your product fits snugly without wasting space or risking damage during shipping.

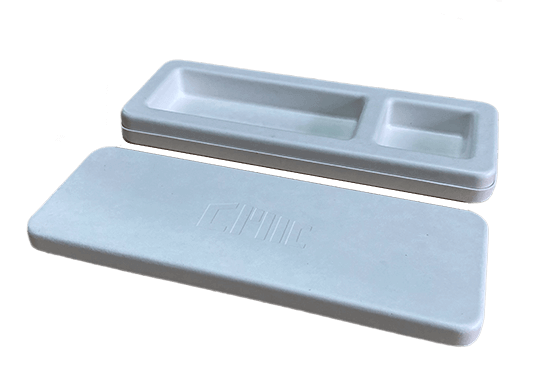

If you have packaging needs but prefer to skip the measuring process, you can also send us your product samples. At C MIC Packaging, we’ll create a tailored packaging solution designed specifically for your product, saving you time and effort.

Choose and Decide on the Right Packaging Size

You’ve measured your product’s dimensions—great job! Now, you need to figure out the right packaging size to keep your product safe and your costs under control. If you’ve never done this before, don’t worry—this step is all about making it easy for you to work with a packaging supplier, like a company that makes paper boxes.

You don’t need to be an expert, but having a basic understanding of how to choose the packaging type and size will help you explain your needs clearly. Let’s break it down into simple steps anyone can follow, focusing on solving your problem: getting a package that works for your product.

- Decide on the minimum packaging size: Your product needs a little wiggle room inside the package to stay safe during shipping. This extra space, called clearance, is where protective materials like bubble wrap or foam go. For most products, add 0.5 to 1 inch on all sides—length, width, and height. For example, if your product is a coffee mug measuring 4 x 4 x 3 inches, your minimum package size should be 5 x 5 x 4 inches to include this clearance. If your product is fragile, like glass, lean toward 1 inch of clearance to be extra safe.

- Think About Protective Materials: Before deciding on a final size, consider what you’ll use to protect your product inside the package. If you’re using something thick, like foam inserts, you’ll need more space. For instance, if you’re packaging a small electronic device and want to use 0.5-inch-thick foam on all sides, add an extra 1 inch to your length, width, and height (0.5 inch on each side). So, if your device measures 6 x 4 x 2 inches, your package size should be at least 7 x 5 x 3 inches.

- Choose a Packaging Type Based on Your Product’s Needs: Now, think about the type of packaging that suits your product. Paper packaging—like corrugated boxes or rigid boxes—is a great starting point because it’s strong, affordable, and eco-friendly. Use corrugated boxes if your product needs tough protection during shipping, like for heavy or fragile items. For example, a set of kitchen knives might go in a corrugated box because it can handle rough handling. Use rigid boxes if your product is lightweight and you want a more polished look, like for a small candle. Knowing your product’s weight and fragility will help you decide.

- Consider Shipping and Storage: Packaging size affects how much you pay for shipping and how much space you need for storage. Bigger packages cost more to ship because many shipping companies charge based on the package’s size, not just its weight. To keep costs down, avoid making your package much bigger than necessary. For example, if you’re shipping a board game that measures 10 x 8 x 2 inches, a package size of 11 x 9 x 3 inches (with clearance) is better than a huge 15 x 12 x 5-inch box, which would waste space and money. Also, think about how your packages will stack in a warehouse—smaller, snug packages are easier to store.

By following these steps, you’ll have a clear idea of the packaging size and type you need, making it easier to work with a packaging supplier. For example, if you’re using a corrugated box for a fragile product, you can tell the supplier, “I need a box that’s at least 5 x 5 x 4 inches to fit my coffee mug with room for protection.” This basic understanding will help you get the right solution without feeling overwhelmed.

But if all this measuring and planning feels like too much work, don’t worry—you can always reach out to us at C MIC Packaging. Our expert packaging team is ready to create a unique packaging solution tailored to your product samples and preferred packaging type, saving you time and effort.

Practical Steps to Determine Packaging Size

Now that you understand the “why” behind packaging size, let’s get into the “how.” These steps are designed to be actionable, whether you’re a designer sketching ideas or a purchasing manager finalizing orders.

Step 1: Create a Mock-Up for a Quick Test

Before committing to a final box size, create a mock-up. This can be as simple as cutting and folding a piece of cardboard to test your dimensions. Place your product, protective materials, and any inserts inside to see how everything fits. Does it feel snug but not cramped? Is there enough room for branding elements?

I remember working with a toy manufacturer who was struggling with oversized boxes for their action figures. We created mock-ups using cardstock and realized they could reduce the box height by 2 inches without affecting protection. The result? Lower shipping costs and a sleeker presentation on retail shelves.

Step 2: Drop Test for Shipping Durability

Once you have a mock-up, test it under real-world conditions. Drop the package from a height of 3 feet (a common standard for shipping tests) to see if the product stays secure. If you’re shipping internationally, consider more rigorous tests, as packages can face rough handling during long journeys.

For example, when shipping from our factories in Shenzhen China to North America or Western Europe, we always recommend clients test their packaging for air, sea, or train transport. A client shipping fragile glassware found that adding an extra 0.5 inch of clearance and using corrugated inserts prevented 95% of breakages, even on turbulent sea routes.

Step 3: Get Feedback from Stakeholders

Don’t work in a silo. Share your mock-up with your team—designers, marketers, and even customer service reps. Designers might suggest tweaks for better branding, while customer service can highlight common complaints, like “the box is too hard to open.”

A great example comes from a luxury candle company we partnered with. Their initial box design was stunning but too large, making it expensive to ship. After feedback from their marketing team, we adjusted the size to fit snugly while adding a magnetic closure for a premium unboxing experience. The result was a win for both cost and customer satisfaction.

How to Size Packaging: Industry Insights

Not all industries have the same packaging needs. What works for a tech gadget might not work for a luxury handbag. Here’s how to tailor your packaging size based on your industry, with insights for packaging buyers, managers, and executives.

E-Commerce: Focus on Shipping Efficiency

If you’re in e-commerce, shipping costs are likely a top concern. Right-sizing your packaging is critical to keeping those costs down, especially for high-volume sellers. Consider using corrugated boxes, which are lightweight yet strong, and opt for custom sizes to avoid dimensional weight penalties.

A real-world example is Amazon’s “Frustration-Free Packaging” initiative, which uses right-sized boxes to reduce waste and shipping costs. Source: Amazon, “Frustration-Free Packaging,”. While you might not have Amazon’s scale, you can achieve similar results by working with a supplier like C MIC Packaging, who can produce custom corrugated boxes tailored to your product range.

Luxury Goods: Prioritize Presentation

For luxury goods, packaging is part of the product experience. Oversized boxes can feel wasteful, but undersized ones can cheapen the brand. Rigid boxes, like the ones we specialize in at C MIC Packaging, are ideal here. They offer a premium look and feel while allowing precise sizing.

Take Chanel, for example. Their iconic black-and-white boxes are perfectly sized to fit their products, with just enough clearance for tissue paper and a ribbon. This attention to detail reinforces their luxury image. If you’re a designer or brand manager, think about how your packaging size can enhance the unboxing experience—sometimes, a slightly larger box is worth it for that “wow” factor.

Food and Beverage: Ensure Safety and Compliance

In the food and beverage industry, packaging size must balance safety, compliance, and shelf appeal. For perishable items, you might need extra space for insulation or cooling packs, while non-perishables can use tighter fits. Always check local regulations—some regions require specific clearance or labeling space.

A client of ours in the organic tea market needed boxes that could fit a cooling pack for their premium blends. We designed a corrugated box with an extra 2 inches of height, ensuring the tea stayed fresh during shipping while keeping costs manageable. If you’re a purchasing manager in this space, think about how packaging size can meet both practical and regulatory needs.

Beyond Size: Cost, Efficiency, and Eco Factors

Now that you have your product’s dimensions, it’s time to think like a purchasing decision-maker or CEO. Packaging size doesn’t just affect product safety—it impacts your bottom line, shipping efficiency, and even your brand’s environmental footprint. Here’s how to strike the right balance.

Cost Considerations: Avoid Oversized Packaging

One of the biggest mistakes I see is businesses choosing oversized boxes to “play it safe.” Sure, it’s tempting to use a one-size-fits-all approach, but this can backfire. Oversized boxes mean higher material costs, more filler materials (like packing peanuts), and increased shipping fees, especially since many carriers now charge based on dimensional weight (the volume of the package) rather than just actual weight.

For instance, DHL Supply Chain’s research showed that optimizing packaging dimensions in their warehouses reduced transportation costs by 7% and improved carton utilization by 7.8%. This demonstrates how even small adjustments in size can lead to significant savings. Imagine you’re shipping 10,000 units a year—those savings add up fast. At C MIC Packaging, we’ve helped clients like a skincare brand reduce their box sizes by 20%, saving them thousands in shipping fees without compromising on protection.

Source: How DHL optimized packaging at warehouses to cut shipping costs

Another compelling example comes from IKEA, which redesigned the packaging for its EKTORP sofa, reducing the package volume by 50%. This optimization allowed IKEA to fit twice as many sofas per shipping container, cutting transportation costs significantly.

Source: Flatpack design helps IKEA thrive during world recession

Efficiency in Production and Storage

Not just the product size and packaing size, you also need to think about how box sizes affect production and storage. Standardized box sizes can streamline your automated production processes, reducing setup times and costs. However, if you’re dealing with a wide range of product sizes, custom packaging might be more efficient.

Consider the example of a global electronics company that optimized its packaging for a range of product sizes. By using modular packaging designs—boxes that could be adjusted to fit different products—they reduced the number of unique box sizes needed by 30%. This not only streamlined their production line but also saved significant storage space in their warehouses, allowing them to store 25% more inventory in the same footprint.

Sustainability: Right-Sizing for the Planet

Sustainability isn’t just a buzzword—it’s a priority for consumers and regulators alike. Oversized packaging wastes materials and increases carbon emissions during shipping. By right-sizing your packaging, you can reduce your environmental footprint and appeal to eco-conscious customers.

Sugarcane bagasse, a byproduct of sugarcane processing, is an excellent material for creating sustainable paper packaging as an emerging favorite in recent years. For example, a study on sustainable packaging found that using bio-based materials like sugarcane bagasse for product packaging can reduce the overall carbon footprint by up to 60% compared to traditional oversized packaging. This is equivalent to significant reductions in greenhouse gas emissions, proving that sustainable packaging choices can make a real difference.

Paper packaging, like the rigid boxes and corrugated boxes we produce at C MIC Packaging, is already more sustainable than plastic alternatives, especially when made from renewable material like sugarcane bagasse. But the real win comes from optimizing size.

For instance, a European retailer we worked with switched to custom-sized eco-box made from sugarcane bagasse, cutting their material usage by 15% and earning praise from customers for their eco-friendly approach. Think about your own brand—how can right-sized, eco-friendly paper packaging enhance your sustainability story?

Summary

Measuring and determining the right packaging size is a critical step to protect your products, reduce costs, and enhance your brand’s image, all while meeting the needs of your industry.

Start by analyzing your product’s dimensions, fragility, and branding needs. Balance cost, efficiency, and sustainability by avoiding oversized packaging and optimizing for shipping. Use mock-ups, durability tests, and stakeholder feedback to finalize your design, and tailor solutions to your specific industry, whether it’s e-commerce, luxury goods, or food and beverage.

Getting the right packaging size isn’t just about saving money—it’s about delivering a seamless customer experience and standing out in a competitive market. Don’t let poor packaging hold your business back—take action now to solve your packaging challenges.

Ready to find the perfect packaging size for your products? Contact C MIC Packaging today to explore custom solutions tailored to your needs.

🎁